I bought a cheap 12V 6A PSU off of ebay last year which I use for powering projects that I’m messing around with. It’s appeared to be working fine until a few months ago when it stopped working.

So I cracked it open, as you do, and found that whoever/whatever soldered this thing did a pretty poor job. Many of the solder joings were dull, and the pins from a number of components, including the large capacitor and the devices connected to the heat sinks, had become unsoldered and were basically sitting in free air.

So I resoldered everything and got it working again, and it’s been (apparently) fine since.

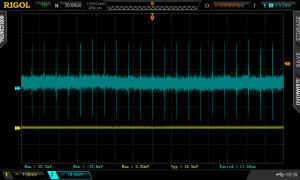

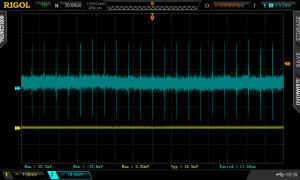

I have recently started playing with an electrec microphone with a view to using it with a MSGEQ7 graphic equaliser. I was breadboarding the microphone and simple transistor amplifier to feed in to the MSGEQ7 and was using my scope to view the wave forms, and noticed this continuous pulsing no matter what point in the circuit I tested

I thought at first it’s something caused by the DC filter capacitor, but I looked at other peoples circuits I didn’t notice this pulsing, so I tried replacing components, with no effect. I briefly thought it might be the scope picking up a 50Hz mains hum, but realised the pulse frequency is too high for that.

I then noticed that even when the scope probes aren’t touching my circuit, the pulse was still there, so I though there was something wrong with the scope. I turned off the PSU to power down my project while I tried to work out what was wrong with the scope, and noticed that the pulse went away. I turned the PSU back on and the pulse came back.

TL, DR

The PSU is somehow introducing some high frequency pulse in to something. I don’t know if it’s in to the mains line, or just some EMI – not really sure how to test either of these.

and A number of the componentsre was hardly any solder around a number of components, and both pins on the large capacitor were not soldered

![]() .

.

Recent Comments